Description

hardware flow control. It is an ideal choice in the field of industrial automation.

3.3 Design of computer control software

This type of control software runs on the computer and is mainly used for remote operation. It has multiple functions such as parameter setting, control operation,

data collection and storage, status detection and alarm, etc. Its interface is shown in Figure 3.

The system shown in Figure 3 contains four independent control channels, and the software can manage and configure the test plan based on parameter information.

That is: for each test plan, you can configure different test plans and set different test parameters through the “Configuration” operation. You can also create new plans,

save and modify plans, open existing plans, and delete plans.

The software also sets up quick operations, which can quickly start and stop work according to the channel configuration, and can detect the working status of

each channel in real time.

3.4 Design of touch screen software

The touch screen software is mainly used for local control and runs in the touch screen controller. While the computer control software has similar functions,

it also has the setting function of local control priority or remote control priority. The default is remote control priority. The login interface and test operation interface

are shown in Figure 4 and Figure 5 respectively.

3.5 Design of PLC software

As the core of this control system, PLC is mainly responsible for the following aspects:

Responsible for sending corresponding control parameters and instructions to the frequency converter, and at the same time obtaining the status

of the transmission system through the ProfibusDP bus protocol.

Communicates with the touch screen through serial communication, responds to local control instructions, and feeds back system status to the touch screen as a slave

computer for local control. Programming between the touch screen and PLC is performed by directly accessing the PLC variable address.

It communicates with the remote control computer through the OPC[5] communication method based on the external network, responds to the remote control instructions

, and feeds back the system status to the remote control computer as the remote control slave. Programming between the remote control program and the PLC is

performed by accessing the PLC variable name.

Process the emergency signal and control the inverter to slow down and unload according to the default parameters.

Figure 4 Login interface

Figure 5 Test interface

3.6 Frequency converter settings

In general, the inverter will be equipped with an optional operation panel. Before using the local or remote control program to operate the inverter,

you must first perform the basic settings of the inverter, as follows:

Switch the control mode to local control and set the inverter address according to the inverter user manual.

Set the inverter for remote control and select the communication mode.

Set the frequency converter to use an encoder, and connect the motor for self-test matching operation.

Set the speed control mode of the inverter, such as speed control or torque control.

After completing the basic parameter settings, switch to the remote control state and wait for remote control.

4 Conclusion

This system implements a universal belt-turning mechanism that utilizes frequency conversion control technology. You can use the local touch screen to

control the inverter to control the motor

rotation and obtain corresponding feedback, or you can use remote control to control the inverter to achieve the same control effect as the local touch screen,

even in view of the computer function The richness allows you to obtain more system information and set more control states. In addition to local touch screen

control and remote control, the overall structure of this system can also be split into the most basic transmission structure to complete the control, that is,

the motor is controlled directly through the

control panel of the frequency converter to achieve the most basic and direct control. Therefore, this system can be used as a basic framework structure to

meet all similar control requirements, and obtain different levels of usage requirements through different levels of hardware configuration, which has universal reference significance.

https://www.xmamazon.com

https://www.xmamazon.com

https://www.plcdcs.com/

www.module-plc.com/

https://www.ymgk.com

V18345-1010121001 ABB TZIDC Electro-Pneumatic Positioner

VE6041F01C1 EMERSON Intelligent switch

Z7128 HIMA CABLE PLUG

2N3A8204-B TOSHIBA PC BOARD ASSEMBLY

4PP220.0571-45 B&R Power Panel PP220 5.7″ QVGA color LC-display with touch screen

YNT511D YOKOGAWA Repeater module

4PP220.0571-65 B&R Power Panel PP220 5.7″ QVGA color LC-display with touch screen

3500/33-01-01 Bently Nevada 16-Channel Relay Module

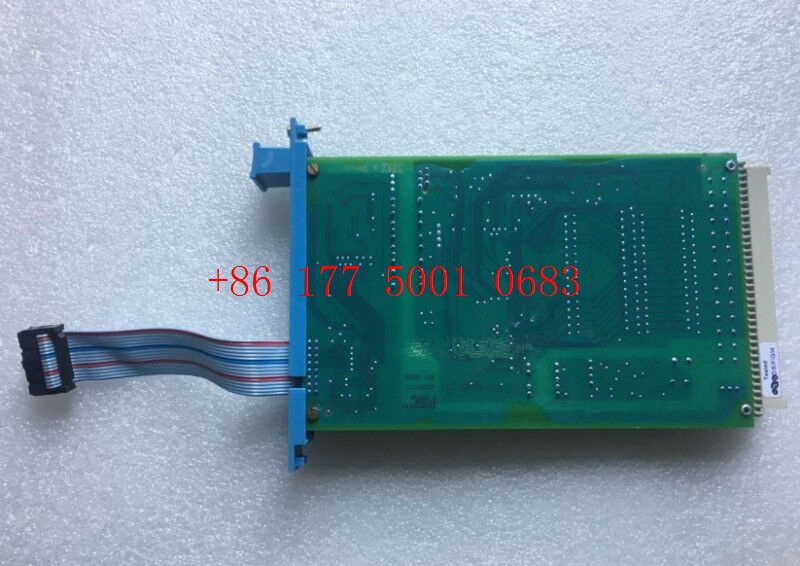

0090-76110 AMAT PCB board

CI871 3BSE092693R1 ABB AC 800M communication interface

FCP280 RH924YA FOXBORO Field Control Processor

IC670ALG310 GE isolated analog output module

IS220PDIAH1A 336A4940CSP1 GE I/O Pack

IW93-2 HESG440356R1 HESG216678B ABB Circuit Board

MVME162-213 MOTOROLA Embedded Controller

M128-010 M128-010-A001B MOOG Controller module

MPS022 13100-203 SCHROFF power-supply module

PFSA140 3BSE006503R1 ABB Roll Supply Unit

PFTL301E 3BSE019050R1000 1.0KN ABB Load cell

PFEA111-20 ABB Tension Electronics

PM851AK01 ABB Controller module

PM856K01 ABB Processor Unit

PM860K01 ABB Processor Unit Kit

PP885 3BSE069276R1 ABB Touch Panel 15,4″

REF610C11LCLR ABB feeder IED

PPD113 PPD103B101 ABB Excitation control system

RMP201-8 KONGSBERG Remote MultiPurpose Input / Output

SBRIO-9607 NI embedded controller

RMP200-8 KONGSBERG DIGITAL OUTPUT MODULE

SPBRC410 ABB Controller with Modbus TCP Interface

ZMI-2002 ZYGO VME Measurement Board

1747-L552 Allen-Bradley Controller module

3HNA023093-001 ABB Controller module

3HAC044168-001 ABB Serial measuring board

1747-L553 Allen-Bradley Processor Unit module

5453-759 Woodward Frame equipment

5466-409 Woodward Power Supply Module

5466-258 Woodward Simplex Discrete I/O Module

5501-376 Woodward Analog I/o Module brand

5501-470 Woodward CPU MODULE

5501-467 Woodward power-supply module

5501-471 Woodward CPU MODULE

8200-226 Woodward Servo Position Controller

8237-1006 Woodward Load Sharing and Speed Control

8200-1302 Woodward Graphical front panel HMI

8237-1006 Woodward Load Sharing and Speed Control

9907-014 Woodward Load Sharing and Speed Control

9907-018 Woodward Load Sharing and Speed Control

9907-019 Woodward Load Sharing and Speed Control

9907-023 Woodward Load Sharing and Speed Control

9907-162 Woodward Digital governor

9907-164 Woodward Digital governor

Reviews

There are no reviews yet.