Description

hardware flow control. It is an ideal choice in the field of industrial automation.

Human-machine collaborative robot technology from seven major companies including ABB and SIASUN

Human-machine collaborative robot is a new type of robot that can work directly side by side with humans without

the need for isolation by safety fences. Human-machine collaborative robots are expected to fill the

gap between fully manual assembly lines and fully automated

production lines. In the past, people often talked about robots replacing human labor, but now robots are considered more

of auxiliary tools. The rigid boundaries between automation and manual labor are gradually being dissolved. Efficient sensors,

intelligent control technology

and the most advanced software technology are integrated on the robot to ensure that humans and robots can cooperate safely

without guardrails and can be flexibly applied without limiting locations and tasks. With this approach, employees can use the required number of

robots at different production locations and for different purposes depending on the required piece quantity.

Advantage

Such sensitive robots can therefore be used, for example, as flexible production assistants in manufacturing and

relieve employees by taking on manual work steps that previously could not be automated and were not ergonomically

correct. For example, by taking on overhead tasks or lifting heavy objects, the burden on employees can be significantly

reduced. Repeatable processes can be carried out with extremely high quality without the need for investments based on type or workpiece.

Representative product introduction

1.ABB’s first human-machine collaborative robot YuMi

abb”s first human-machine collaborative robot, the 14-axis robot YuMi, was announced by UL (Underwriters Laboratories)

on September 22, 2015 to have obtained UL safety certification, highlighting its key safety design with human-machine

collaboration capabilities. UL stated that ABB”s first dual-arm industrial robot YuMi that emphasizes human-machine

collaboration has obtained the robot safety certification from UL. This not only brings indexical significance to the unit robot”s

move towards human-machine interaction, but also ignites industrial momentum and provides support for the sustainable development and

development of the robot industry. Popularize the use of injectable cardiotonic injections.

Tang Jiade, general manager of UL Taiwan, said, “The certification process for robots with human-machine collaboration

and multiple axes is complicated. Taking YuMi”s 14-axis arms as an example, there are 14 degrees of freedom for translation

and rotation. Combining them produces more With

fast movements, UL relies on its professional experience in safety to simulate various failure scenarios for evaluation based on

different applications of robots to ensure that the robot can not only interact smoothly with people, but also interact smoothly with people in every

situation. Be able to self-detect and maintain safety and reliability.”

Cai Jingchun, associate director of ABB Taiwan”s industrial robot department, said, “ANSI/UL1740 robot and

automation equipment standard is not only a commercial standard, but also a national standard recognized by the

American National Standards Institute (ANSI). It has been certified by UL with global credibility, symbolizing YuMi”s Safety

design has been rigorously and

objectively evaluated and tested, and can lead the global industry to truly enter Industry 4.0/advanced manufacturing.”

2. Universal Robots’ flexible and safe full range of collaborative robot families

Universal Robots is a pioneer in a new segment of collaborative robots that focuses on user operability

and flexibility. At the Shanghai International Automobile Manufacturing and Assembly Exhibition from August 26 to 28, 2015

, Universal Robots” full range of collaborative robot families were unveiled.

The “human-robot collaboration” function of UR robots allows employees to work safely and closely with robots. The unique force sensing

allows it to automatically limit the amount of force generated during contact once it collides with a person. For example, the

default force sensing upper limit is set to a force of 150 Newtons. That is, once a person comes into contact with the

robot and a force of 150 Newtons is generated, the UR robot will automatically stop working. But it can also be adjusted

to automatically stop working once it encounters a force as low as 50 Newtons on the working path. In addition, the

UR robot has an intuitive user programming interface, and the robot movement direction can be controlled by clicking the

arrows on the touch panel. For workers, simple installation, debugging, and programming can be completed without

professional technical background or professional programming experience. These unique advantages have made UR

robots favored by many automobile manufacturers around the world.

Universal Robots currently has three collaborative robots – UR3, UR5 and UR10. The newly launched UR3 in March

2015 is the most flexible and lightweight desktop robot on the

market today that can work side by side with workers. It weighs only 11 kilograms, but has a payload of up to 3 kilograms.

All wrist joints can rotate 360 degrees, and the end joints can rotate infinitely. UR5 has a dead

weight of 18 kg, a payload of up to 5 kg, and a working

radius of 85 cm. UR10 can carry 10 kg and has a working radius of 130cm. All three robots are renowned in the industry

for their ease of programming, collaboration, safety and reliability when working with people.

It is reported that the UR robot also has an intuitive user programming interface, and you can control the robot”s

movement direction by clicking the arrows on the touch panel.

3. FANUC collaborative robot CR-35iA with the largest payload

The maximum load on the wrist of the CR-35iA robot reaches 35kg, and the movement radius can reach

1813mm. As a collaborative robot, the complete safety functions allow the CR-35iA to work in the same space

with people without isolation by safety fences. The excellent design also enabled the CR-35iA to win the Industrial

Design Gold Award at this year’s Industry Expo, which was personally awarded by Vice Premier Ma Kai of the State Council.

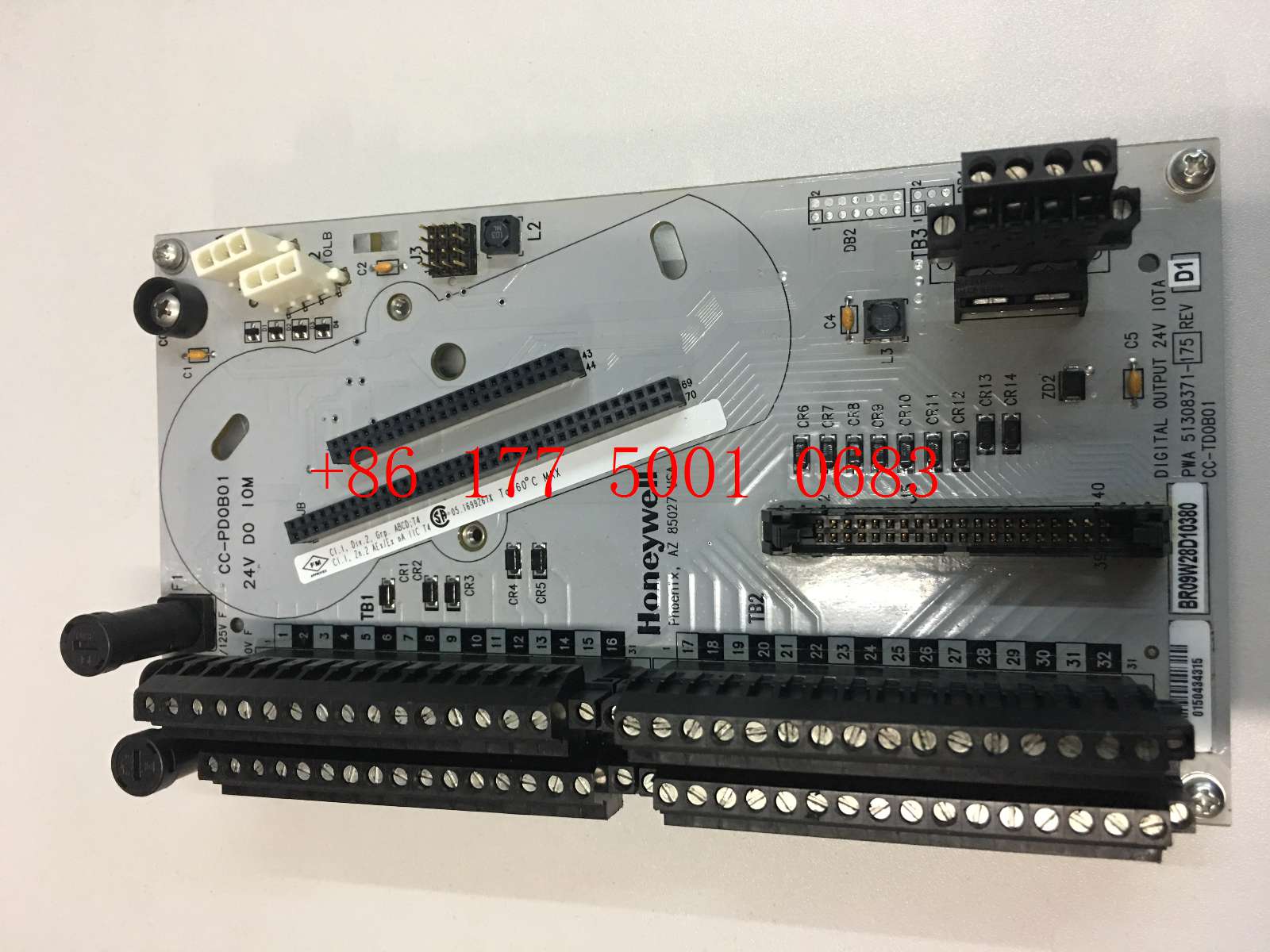

CC-PAOX01 51405039-275 HONEYWELL Analog Output Module

CC-PAON01 51410070-175 HONEYWELL Analog Output Module

CC-PAOH01 51405039-175 HONEYWELL HART Analog Output Module

CC-PAIN01 51410069-175 HONEYWELL Analog Input Module

CC-PAIX01 51405038-275 HONEYWELL Experion High Level Analog Input Module

CC-PAIH51 51410069-275 HONEYWELL Analog Input Module

CC-PAIH01 51405038-175 HONEYWELL Analog Input with HART

CC-PAIH02 51405038-375 HONEYWELL C300 Hart Analog Input

6DD1683-0BC5 Siemens Power Supply

1746-NI16I Allen-Bradley SLC 500 Analog I/O Module

1C31125G02 Westinghouse Digital Output Module

1X00781H01L EMERSON POWER SUPPLY

1C31132G01 Westinghouse Analog Output

P0904HN LZS 1500-3FOX FOXBORO Power module

CR-GEN0-M6400R3 DALSA High speed CCD line scanning camera

DSQC661 3HAC026253-001 ABB Power Supply

DTDX991A 61430001-UW ABB Analog Module

DSQC609 3HAC14178-1 PBSE5117 ABB Power Supply

1747-BA Allen-Bradley SLC 500 Lithium Battery

5SHX06F6004 3BHB003387R0101 ABB IGCT module

DTCC901B DCC2390A ABB Excitation system controller

651T-0600 Acromag Single Channel Process Current Transmitter/Isolator

12KM02E-V0002 3EGM030300R0002 ABB Multi-axis control unit

T8448 ICS Triplex Trusted TMR 24Vdc Zone Interface Module

T8161B ICS TRIPLEX Trusted TMR Processor

P026MX FOXBORO Fbm Modules

P0916VL FOXBORO Termination Cable

P0916VB FOXBORO Termination Cable

FBM240 P0917GZ FOXBORO DCS CARD MODULE FBM

FBM208 P0914TB FOXBORO Redundant 0-20 Module w/Readback

FBM206 P0916CQ FOXBORO Terminal Assembly

FBM204 P0914SY FOXBORO Channel Isolated

FBM202 P0926EQ FOXBORO Channel Isolated 8 Input

FBM201e P0924TR FOXBORO Analog Input Interface Modules

FBM201D P0922YK FOXBORO Analog Input Interface Modules

57552-4 RELIANCE Universal Drive Controller Module

57405 Reliance I/O Analog DCS Module

57401 RELIANCE Digital I/O Drive

57C430 RELIANCE Processor Module 6010

TRICONEX CM2201 TRICONEX Communication Module

57C404C RELIANCE COMMUNICATION NETWORK MODULE

VME162PA-344SE Motorola Embedded Controller

57652 0-57652-D RELIANCE Universal Drive Controller Module

57C443 RELIANCE Remote I/O Scanner Module

57C435 RELIANCE 7010 Series Processor Module

57C409 RELIANCE 2 Channel Analog Input Module

57C411 RELIANCE Resolver Input Module

57C410A RELIANCE Analog Output Module

57C404C RELIANCE COMMUNICATION NETWORK MODULE

Reviews

There are no reviews yet.