Description

hardware flow control. It is an ideal choice in the field of industrial automation.

Implementation of communication between ABC industrial robot and PLC based on DeviceNet fieldbus technology

introduction

In modern production systems, industrial robots and PLCs need to communicate and collaborate to complete production tasks. That is, the

industrial robots output signals to the PLC, allowing the PLC to control related equipment to drive the robot”s front-end tools. This article

mainly analyzes the communication problems between ABB industrial robots and PLC based on DeviceNet fieldbus technology.

DeviceNet is a common network communication method in the field of automation. ABB industrial robots establish a network to communicate with

Siemens PLC based on the DeviceNet network.

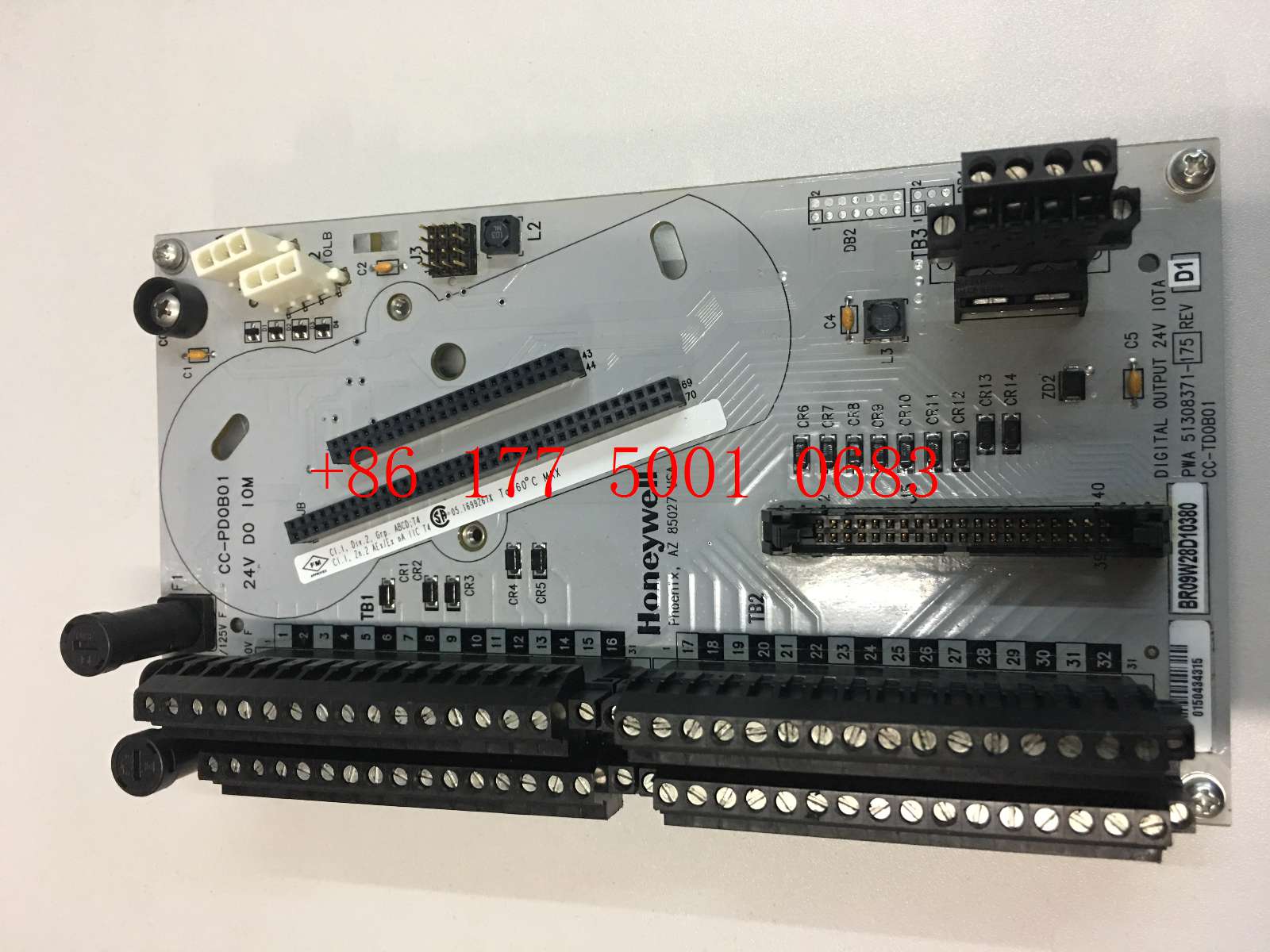

1Configure DSQC652

There are mainly 5 types of standard I/0 boards commonly used in ABB industrial robots [2]. Except for the different addresses assigned to

them during setup, their configuration methods are basically the same. This article mainly analyzes the ABB standard I/0 board DS0C652, which

mainly builds communication modules based on the DeviceNet network. The DS0C652 board has a distributed I/O module with 16 digital input and 16

digital output interfaces. The board is installed in the ABB industrial robot control cabinet. First, define the specific operation steps of the DS0C652 board,

enter the teach pendant control panel, then enter the configuration menu (Figure 1), select the DeviceNetDevice menu, and add a template to enter Figure 2.

ABB standard I/0 board is hung on the DeviceNet

network, so the address of the module in the network must be set. The jumpers 6 to 12 of terminal x5 are used to determine the address of the module.

The available address range is 10 to 63. Modify the parameters in the template parameters to complete the DS0C652 board settings. Click the drop-down

menu to select the “Use value from template” row, select

“DS0C65224VDCI/0Device”, and then the parameters that need to be set include the address of the I/0 board in the bus.

Figure 1 Configuring DSQC652

2Configure signals and parameters

After completing the DS0C652 board setting, the I/0 signal setting will be performed. Setting the I/0 signal is the basis for establishing communication with

the PLC. The PLC communicates and transmits data with the ABB industrial robot through the I/0 signal and the DS0C652 board. As shown in Figure 3, in the

signal configuration interface, there are many default I/0 points after the system is established. Modification is not allowed. Click “Add” to add signals. When setting

input and output signals, their address range is 0~15. First, enter the signal menu in the configuration options to set the input and output types, and modify the corresponding parameters.

After completing the settings, the computer prompts that you need to restart the settings. If there are multiple signals that need to be defined and the waiting time

is long after restarting multiple times, you can click “Cancel” and wait for all signals to be defined before clicking the “Yes” button to restart. After the signal settings are

completed, click to select “Input and Output” in the ABB menu to check whether all signals have been set.

Figure 2 Configure DSQC652 parameters

Figure 3 Signal parameter settings

During the signal establishment process, attention should be paid to the DSoC652 port and PLC port addresses used, and the corresponding address table should be

established, as shown in Table 1. The robot interacts with the PLC through I/O signals. During the setting process, there must be no errors in the port and address number

of the PLC connected to the DSoC652. If the address is set incorrectly, the communication between the robot and the PLC will not work properly.

The entire robot teaching pendant setting process is shown in Figure 4.

https://www.xmamazon.com

https://www.xmamazon.com

https://www.plcdcs.com/

www.module-plc.com/

https://www.ymgk.com

F3322 | HIMA | F 3322 16 fold output module

F5220 | HIMA | F 5220 2 fold counter module

F3248 | HIMA | F 3248 16-fold input module

F3240 | HIMA | F 32404 16-fold input module

F3237 | HIMA | F 3237 16-fold input module

F3224 A| HIMA | F3224A 4 16-fold input module

F3223 | HIMA | F 3223 4 fold input module

F3222 | HIMA | F 3222 digital input module

F3221 | HIMA | F 3221 16-fold input module

F7126 | HIMA | F 7126 power module

F7130A | HIMA | F 7131 power module

F7126 | HIMA | F 7126 power module

F8653X | HIMA | F8653X Central module

F8651X | HIMA | F8651X controller module

F8652X | HIMA | safety-related CPU

F8652X | HIMA | F 8652X safety-related CPU

F8653X | HIMA | F8653X Central module

B5233-2 | HIMA | B 5233-2 Assembly kit

B5233-1 | HIMA | B 5233-1 Assembly kit

B5231 | HIMA | B 5231 Assembly kit

B4237-2 | HIMA | B 4237-2 Assembly kit

B4237-1| HIMA | B 4237-1 Parts of the assembly kit

B4235 | HIMA | B 4235 Assembly kit

B4233-2 | HIMA | B 4233-2 Parts of the assembly kit

SPBRC410 | ABB | Analog output module

SPASO11 | ABB | Analog output module

SPAJ140C-CA | ABB | Overcurrent and Ground Fault Relays

SNAT7640 3BSE003195R1 | ABB | Sell Control System Parts

YPK111A/YT204001-HH | ABB | control system parts

YPK107E/3ASD489301A410 | ABB | control system parts

YPI103E/YT204001-FB | ABB | off-the-shelf module

YPG111A 3ASD273001B1 | ABB | terminal interface

YPG110E YT204001-FD/1 | ABB | off-the-shelf module

DCF1048880P0001 YPC111B | ABB | YPC 111B adapter module

YL681001-AB | ABB | speed terminal

XZ727A-E GJR2323300R0001 | ABB | Bailey module

XV C768 AE102 | ABB | XVC768AE102 adapter module

XT376A-E HEIE420158R1 | ABB | module

B4231 | HIMA | B 4231 system module

XR8981V3 HEIE431105P1 | ABB | adapter module

XT377E-E HESG446624R1 | ABB | module

UT735A-E GJR2328100R0001 | ABB | adapter module

UT635A-E GJR2910300R0001 | ABB | Programmable Control System

ZMU-02 3AUA0000151291 | ABB | Inverter memory card

3AUA0000040000 RUSB-02 | ABB | Laptop Cable Kit

UAD142A01 3BHE012551R0001 | ABB | Extended output power supply

REU615 | ABB | Voltage Protection and Control Relays

UNITROL 1020 UNS0119A-Z,V1 3BHE030579R0003 | ABB | Excitation System

SPHSS03 | ABB | Hydraulic Servo Module

REM615E_1G HBMBCAAJABC1BNN11G | ABB | Feeder Protection and Control Relays

UAD155A0111 3BHE029110R0111 | ABB | Distributed Control System Module

CS513 3BSE000435R1| ABB | communication interface module

Reviews

There are no reviews yet.